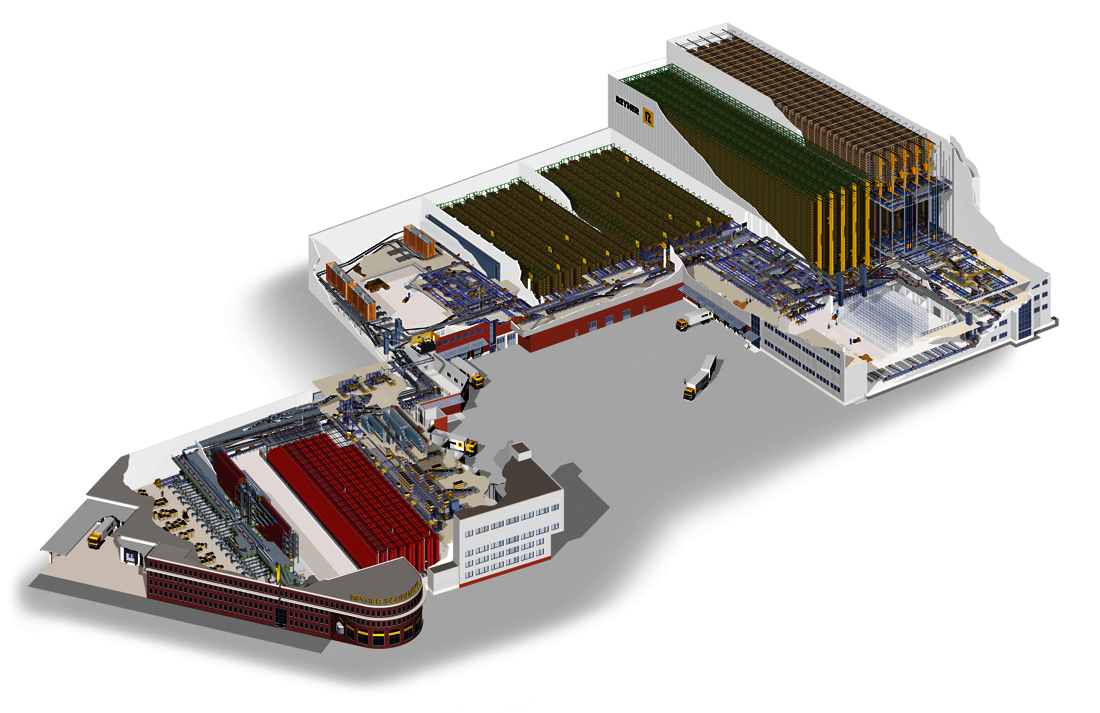

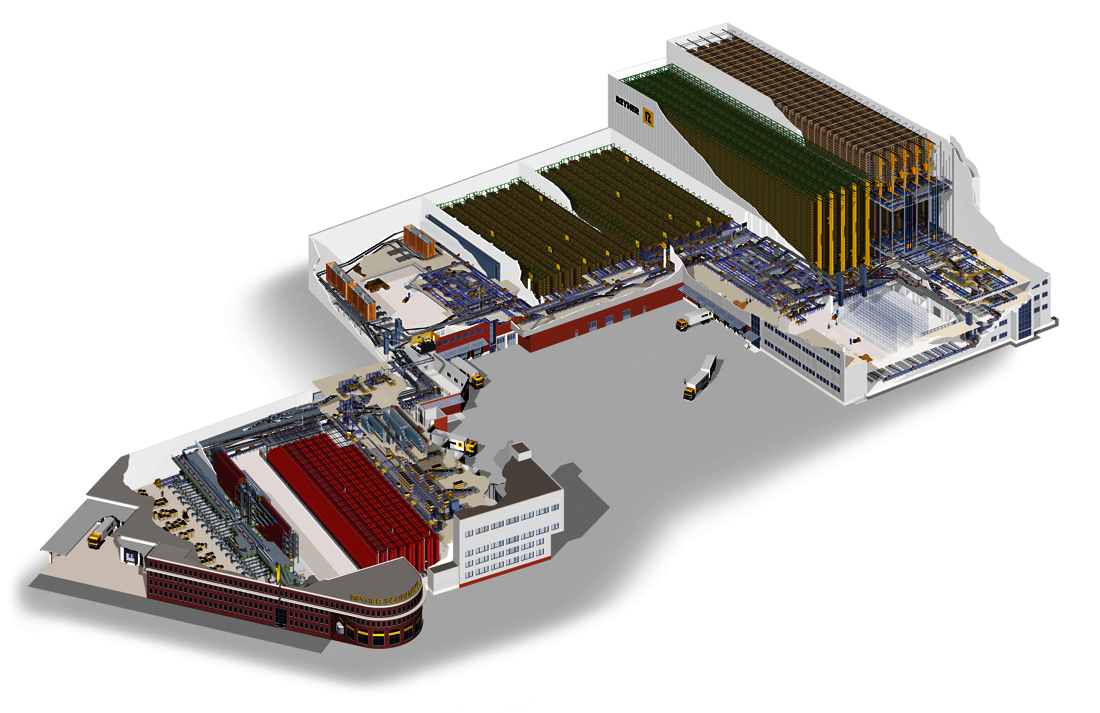

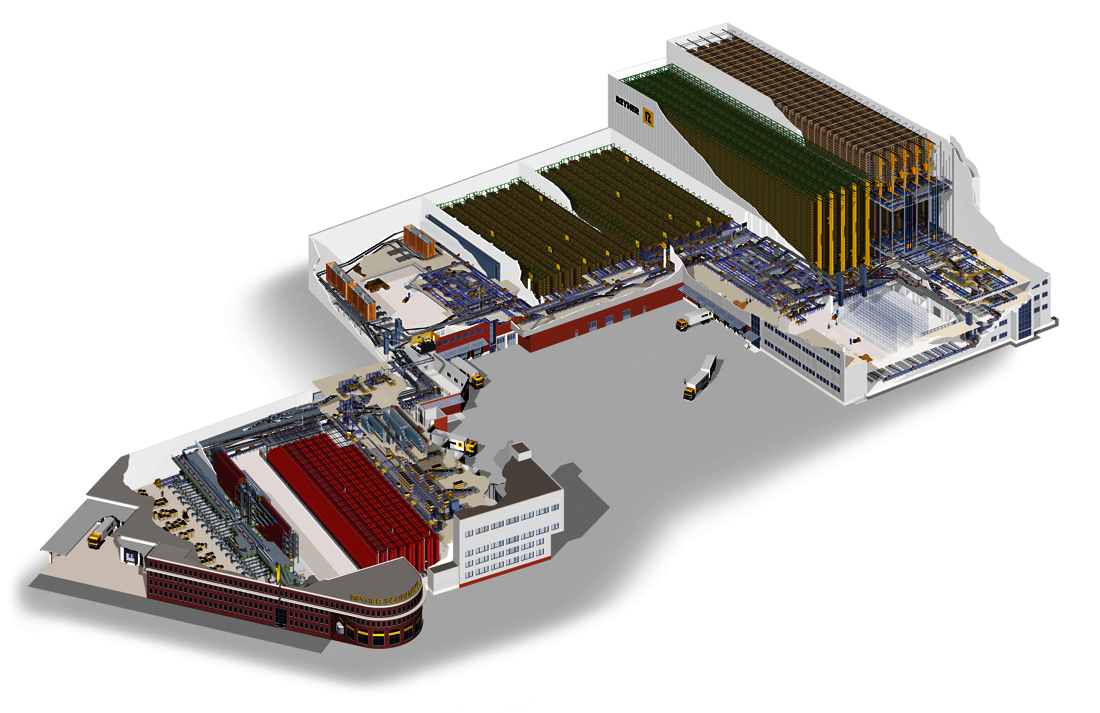

A look behind the scenes

What does it actually look like behind the gates of a wholesaler for fasteners and fixing technology? To give you an interesting insight, we have captured our 16 "hot spots" on the company premises in Hamburg in 360° views for you. Click on the map and on the markers to view.

Click on a marker for a 360° view

Tap on the image for an interactive view

Click on a marker for a 360° view

More about REYHER: